Cost To Replace Hardie Board Siding

Cost to replace Hardie board siding? It’s a bigger project than you might think! This guide breaks down the costs, from materials and labor to surprises. We’ll cover everything you need to know to get accurate estimates and choose the right contractor, ensuring your Hardie board siding replacement goes smoothly and within budget.

Replacing Hardie board siding involves several key factors influencing the final cost. House size directly impacts material and labor needs. The type and color of the Hardie board you choose also affect pricing, as do regional labor rates. Don’t forget about permits, waste disposal, and potential underlying repairs – these add up quickly. We’ll explore all these aspects, offering practical tips and cost comparisons to help you plan your project effectively.

Factors Influencing Hardie Board Siding Replacement Costs

Replacing Hardie board siding is a significant home improvement project, and the total cost can vary widely depending on several key factors. Understanding these factors will help you budget accurately and make informed decisions. This section will break down the major cost drivers to give you a clearer picture.

House Size Impact on Replacement Costs

The size of your house is the most significant factor influencing the overall cost. Larger houses require more materials and labor, directly increasing the expense. For example, a 1,500 square foot house will naturally cost less to re-side than a 3,000 square foot house. The cost per square foot might remain relatively consistent, but the total cost will be substantially higher for larger projects. Consider measuring your home’s exterior square footage accurately to get a more precise estimate.

Hardie Board Type and Color Price Variations

Hardie board siding comes in various types and colors, each affecting the final price. Premium options, such as those with enhanced textures or thicker boards, will cost more than standard options. Similarly, some colors may require more specialized paints or finishes, leading to additional expenses. For instance, custom colors or intricate patterns may add a premium to the cost of the materials. Check with your supplier for price lists specific to your chosen materials.

Labor Costs in Different Geographical Regions

Labor costs vary considerably depending on your location. Areas with higher costs of living generally have higher labor rates for contractors. Metropolitan areas tend to have higher labor costs than rural areas. For instance, a siding replacement project in New York City will likely cost more in labor than a similar project in a smaller town in the Midwest. Getting multiple quotes from local contractors is essential to understand the prevailing labor rates in your area.

Additional Costs: Permits and Disposal Fees

Beyond material and labor costs, you’ll likely encounter additional expenses. Most localities require permits for exterior home renovations, involving fees that vary based on the project’s scope. Proper disposal of old siding also incurs costs, including landfill fees or recycling charges. These fees can add several hundred dollars to the total project cost. Check with your local building department to determine permit requirements and associated fees.

Professional vs. DIY Installation Cost Comparison

| Factor | Professional Installation Cost | DIY Installation Cost | Cost Difference |

|---|---|---|---|

| Materials | $5,000 – $10,000 (depending on house size and material choices) | $5,000 – $10,000 (same as professional) | $0 |

| Labor | $6,000 – $15,000 (depending on house size and location) | $0 – $2,000 (potential for significant cost savings, but also risk of mistakes) | $4,000 – $15,000 |

| Permits | $200 – $500 | $200 – $500 | $0 |

| Disposal | $300 – $800 | $300 – $800 (potentially lower if you handle some aspects yourself) | $0 – $500 |

| Total Estimated Cost | $11,500 – $25,500 | $5,500 – $12,300 | $6,000 – $13,200 |

Note: These are estimates and actual costs may vary significantly. DIY costs assume you have the necessary tools, skills, and time. Mistakes in DIY installation can lead to higher costs than anticipated.

Material Costs for Hardie Board Siding Replacement

Replacing your siding with Hardie board involves significant material costs. These costs vary depending on several factors, including the type of siding chosen, the amount needed, and current market conditions. Understanding these variables is crucial for accurate budgeting.

Hardie board siding, while a premium product offering durability and longevity, represents a substantial investment. This section breaks down the key material cost components to help you better understand the overall expense.

Hardie Board Manufacturer Price Comparison

While James Hardie is the most widely recognized brand, other manufacturers offer comparable products. Price differences between brands can be subtle, often varying by region and retailer. However, it’s generally advisable to obtain quotes from multiple suppliers to compare not only the price per square foot but also the overall package deal, including trim and fasteners. Direct comparisons are difficult without specific product lines and geographic locations but expect minor variations rather than dramatic price swings between reputable manufacturers. Consider the warranty and reputation of each brand as part of your decision-making process.

Cost Differences Between Siding Styles

Different Hardie board siding styles influence material costs. Lap siding, the most common type, is generally less expensive per square foot than more complex styles like shingles or vertical planks. Shingles, mimicking the look of traditional wood shingles, often require more pieces and more intricate installation, leading to higher material and labor costs. Vertical planks, while aesthetically pleasing, can also increase the overall material cost due to their size and unique installation requirements. The complexity of the design directly correlates with the final price. For example, a simple lap siding installation might cost $8-$12 per square foot in materials alone, whereas shingle siding could easily reach $12-$18 or more.

Cost Savings Through Bulk Purchasing

Purchasing materials in bulk can often lead to significant cost savings. Most suppliers offer discounts for larger orders. However, accurately estimating your needs is critical to avoid overspending. Overestimating your material requirements can result in wasted resources and additional disposal costs. It’s best to work closely with your contractor to determine the precise quantity needed based on detailed measurements of your home’s exterior.

Impact of Material Availability and Supply Chain Issues

Material availability and supply chain disruptions can significantly impact pricing. During periods of high demand or supply chain bottlenecks, prices can fluctuate dramatically. It’s advisable to plan your project well in advance to mitigate potential delays and cost increases. Monitoring market trends and speaking with your contractor about potential supply chain risks can help you prepare for unexpected changes.

Typical Costs Associated with Each Material Component

Understanding the individual cost components helps in creating a more accurate budget. Prices are estimates and can vary depending on location, supplier, and current market conditions.

- Hardie Board Siding: $1.50 – $5.00 per square foot (depending on style and thickness)

- Trim Boards (J-channels, corner boards, etc.): $2.00 – $8.00 per linear foot

- Fasteners (nails, screws): $10 – $30 per box (depending on quantity and type)

- Flashing and Sealants: $50 – $150 per project (depending on size and complexity)

- Underlayment (if required): $0.50 – $2.00 per square foot

Labor Costs and Contractor Selection

Source: angi.com

Replacing Hardie board siding involves significant labor costs, often exceeding material expenses. Understanding these costs and choosing the right contractor is crucial for a successful and budget-friendly project. This section will guide you through evaluating labor costs, comparing contractor experience levels, and selecting a reliable professional for your siding replacement.

Labor Cost Ranges

Labor costs for Hardie board siding installation typically range from $2 to $8 per square foot, depending on several factors. The lower end of this range often applies to simpler projects with minimal prep work, while the higher end reflects more complex jobs involving extensive repairs, intricate designs, or difficult-to-access areas. For example, a straightforward replacement on a single-story house with minimal prep might fall closer to $2-$4 per square foot, whereas a multi-story home requiring significant repairs and intricate trim work could easily reach $6-$8 or more. This variation highlights the importance of getting multiple bids to accurately assess the cost for your specific project.

Experienced vs. Less Experienced Contractors

Experienced contractors generally charge higher hourly rates, typically ranging from $50 to $100 or more per hour. Their higher rates reflect their expertise, efficiency, and experience in handling complex situations and ensuring a high-quality finish. Less experienced contractors might charge between $30 and $70 per hour, but their work may take longer and potentially require more oversight. While the lower hourly rate might seem attractive, remember to consider the potential for delays, rework, or lower-quality results that could ultimately increase the overall cost.

Contractor Selection Factors

Choosing the right contractor is paramount. Several key factors should be considered:

- Licensing and Insurance: Verify that the contractor possesses the necessary licenses and insurance, including worker’s compensation and liability insurance. This protects you from potential financial liability in case of accidents or damages.

- Reviews and References: Check online reviews on platforms like Yelp, Google My Business, and Angie’s List. Request references from previous clients to gauge their satisfaction with the contractor’s work, communication, and professionalism.

- Experience and Expertise: Look for contractors with proven experience in Hardie board siding installation. Inquire about the types of projects they’ve completed and their familiarity with the specific Hardie board products you’re considering.

- Detailed Contract: A comprehensive contract should Articulate the scope of work, payment schedule, materials used, warranty information, and project timeline. Carefully review the contract before signing.

Obtaining Multiple Contractor Bids

Getting at least three bids from different contractors is essential for comparison. Provide each contractor with the same detailed description of your project, including specifications, measurements, and desired materials. This allows for a fair and accurate comparison of their pricing and services. Remember to compare not just the price but also the contractor’s experience, reputation, and the overall value they offer.

Questions to Ask Potential Contractors

Before hiring a contractor, it’s vital to ask specific questions to clarify aspects of the project and assess their professionalism.

- What is your experience with Hardie board siding installation?

- Can you provide references from previous clients?

- What is your process for handling unforeseen issues or delays?

- What is your warranty policy for the installation?

- What is your payment schedule?

- Do you have liability and worker’s compensation insurance?

- What is your estimated timeline for completing the project?

- Can you provide a detailed breakdown of the cost estimate?

Preparation and Pre-Installation Costs

Source: freemansconstruction.com

Getting your home ready for new Hardie board siding involves more than just slapping up the new panels. Significant costs can be associated with the preparation phase, impacting your overall budget. Understanding these upfront costs is crucial for accurate project planning and avoiding unpleasant surprises.

Pre-installation work significantly influences the final cost and longevity of your new siding. Ignoring these steps can lead to problems down the line, such as premature siding failure or even structural damage. Let’s break down the key expenses.

Existing Siding Removal Costs

Removing old siding is rarely a quick or easy task. The cost depends heavily on the type of siding being removed (vinyl, wood, etc.), its condition (fragile, weathered, etc.), and the accessibility of the house (multiple stories, difficult terrain, etc.). Labor costs are the major factor here. Expect to pay anywhere from $1 to $5 per square foot, with more complex removals at the higher end. For example, removing asbestos siding requires specialized handling and disposal, adding substantially to the cost. In a 1,500-square-foot home, removing old wood siding might cost between $1,500 and $7,500, while asbestos removal could easily double or triple that amount.

Underlying Sheathing and Structure Repair Costs, Cost to replace Hardie board siding

Once the old siding is off, you’ll likely find areas needing repair. This could include replacing rotted or damaged sheathing, fixing water damage to the underlying structure, or addressing insect infestation. The cost varies wildly depending on the extent of the damage. A small area of rotted wood might cost a few hundred dollars to repair, while extensive structural damage could easily run into the thousands. For instance, replacing a section of damaged plywood sheathing might cost $200-$500 in materials and labor, while repairing significant water damage could involve framing repairs costing $1000 or more.

Surface Preparation Costs

Before installing new siding, the surface must be properly prepared. This includes cleaning the existing sheathing, repairing any gaps or holes, and ensuring a level surface. This often involves caulking, priming, and potentially installing new flashing around windows and doors. The cost here is typically less than the previous steps but still adds up. A typical cost for surface preparation might range from $0.50 to $2.00 per square foot, depending on the complexity of the job. In an 11,500-square-foot home, this could range from $750 to $3,000.

Unexpected Costs During Preparation

Unforeseen issues are common during demolition and preparation. Discovering hidden water damage, extensive insect infestation, or asbestos requires additional work and specialized contractors, significantly increasing the budget. For example, discovering asbestos siding during removal adds several thousand dollars to the project, depending on the amount of asbestos present and the disposal requirements. Similarly, discovering extensive termite damage can add thousands of dollars in treatment and structural repair.

Step-by-Step Pre-Installation Cost Breakdown Example

Let’s consider a hypothetical 1,500-square-foot home with moderate pre-installation needs:

| Task | Cost Estimate |

|---|---|

| Existing Siding Removal (Wood Siding) | $3,000 – $4,500 |

| Sheathing Repair (Minor Rot) | $500 – $1,000 |

| Surface Preparation (Cleaning, Caulking, Priming) | $1,500 – $2,250 |

| Total Estimated Pre-Installation Cost | $5,000 – $7,750 |

Remember, this is just an example. Your actual costs will depend on your specific circumstances. Always get multiple bids from reputable contractors to ensure you’re getting a fair price.

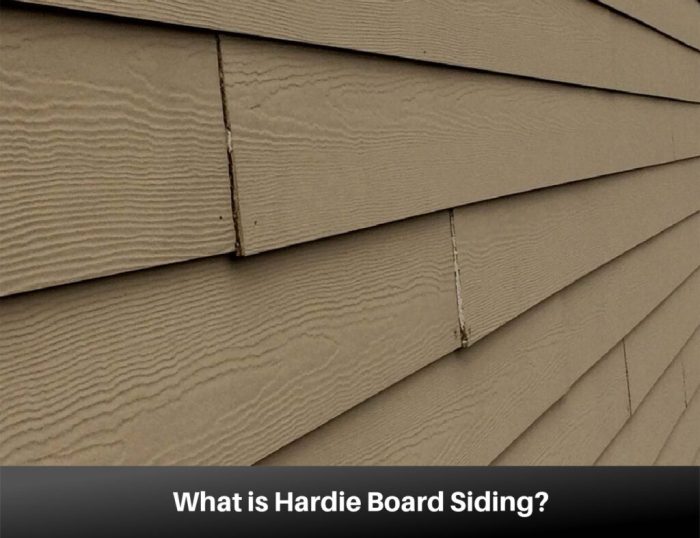

Visual Examples of Hardie Board Siding Projects: Cost To Replace Hardie Board Siding

Seeing is believing, and when it comes to choosing Hardie board siding, visualizing different projects helps you understand the possibilities and costs involved. Below are some examples showcasing various styles and price points, illustrating how material choices and project complexity influence the final cost. Remember that these are estimates and actual costs may vary depending on location, labor rates, and specific project needs.

High-End Hardie Board Siding Project

This project features premium Hardie board siding with intricate detailing, such as custom-cut trim pieces, multiple colors and textures, and accents like stone or brick veneer. The home likely has complex architectural features, including dormers, bay windows, and multiple rooflines requiring careful siding installation. The siding might incorporate a variety of textures, such as smooth lap siding on the main walls and textured shingles for accents. A high-end project also often includes upgraded installation techniques, such as specialized flashing and sealant applications to ensure superior weather protection. The estimated cost for a high-end Hardie board siding project on a 2,500 sq ft home could range from $25,000 to $40,000 or more. This cost includes premium materials, skilled labor, and meticulous attention to detail.

Mid-Range Hardie Board Siding Project

A mid-range project balances quality with affordability. It uses standard Hardie board siding in one or two colors, with simpler trim work and fewer architectural details. The installation might involve standard lap siding with some accent pieces, perhaps around windows and doors. While the materials are still high-quality, they might not be the top-of-the-line options. The project focuses on a clean, attractive look without excessive ornamentation. For a 2,500 sq ft home, a mid-range Hardie board siding project could cost between $15,000 and $25,000. This range considers reasonable material choices and a skilled but not necessarily specialized installation team.

Budget-Friendly Hardie Board Siding Project

A budget-friendly project prioritizes cost-effectiveness without sacrificing quality. This typically involves using a single color of standard Hardie board lap siding with minimal trim. The installation is straightforward, focusing on efficient coverage rather than elaborate detailing. While the overall aesthetic is simple and clean, it still provides the durability and longevity associated with the Hardie board. For a 2,500 sq ft home, a budget-friendly project might cost between $10,000 and $15,000. This lower cost reflects the use of standard materials and a more streamlined installation process.

Complex Hardie Board Installation

Imagine a two-story home with multiple gables, dormers, and intricate window and door surrounds. This project requires precise measurements, careful planning, and specialized cutting techniques to accommodate the various angles and curves. The installation may include extensive use of trim pieces, corner boards, and flashing to ensure a watertight seal around all architectural features. The labor costs for this type of project will be significantly higher due to the increased time and expertise needed. The estimated cost for such a complex project could easily exceed $30,000, depending on the size of the house and the extent of the intricate details.

Simple Hardie Board Installation

This involves a single-story home with a simple rectangular shape and minimal architectural features. The siding installation is relatively straightforward, using standard lap siding with basic trim around windows and doors. The project requires less planning and fewer specialized cuts, resulting in lower labor costs. For a 1,500 sq ft single-story home, a simple Hardie board installation could cost between $8,000 and $12,000. This lower cost reflects the straightforward nature of the installation and the reduced material needs.

Closing Summary

Source: homedit.com

Replacing Hardie board siding is a significant investment, but with careful planning and research, you can manage costs effectively. Remember to factor in all aspects – materials, labor, permits, and potential unforeseen expenses. Getting multiple bids from reputable contractors, understanding the different Hardie board options, and considering DIY versus professional installation are crucial steps. By weighing these factors, you can confidently embark on your Hardie board siding replacement project, transforming your home’s exterior while staying within your budget.

Question & Answer Hub

Can I replace Hardie’s board siding myself?

While possible, DIY installation is significantly more labor-intensive and may void warranties. Weigh the cost savings against the time commitment and potential for mistakes.

How long does Hardie board siding replacement typically take?

The timeframe varies greatly depending on house size, complexity, and weather conditions. Expect several days to several weeks for a professional installation.

What is the typical lifespan of Hardie board siding?

Hardie board siding is known for its durability, lasting 30-50 years or more with proper maintenance.

Does Hardie board siding require regular maintenance?

Minimal maintenance is needed, primarily involving occasional cleaning to remove dirt and debris. Check for any damage and address it promptly.

Are there different warranties for Hardie board siding?

Yes, warranties vary by manufacturer and product type. Check the specific warranty information for the siding you choose.